Continuous Casting Applications

The Use of Graphite in Continuous Casting Technology

Continuous casting is a modern production method in which liquid metal is solidified in a controlled manner, transforming it into a semi-finished product. This method allows for the production of wires, cylindrical rods, tubular profiles, strips, and semi-finished products with special cross-sections with high efficiency.

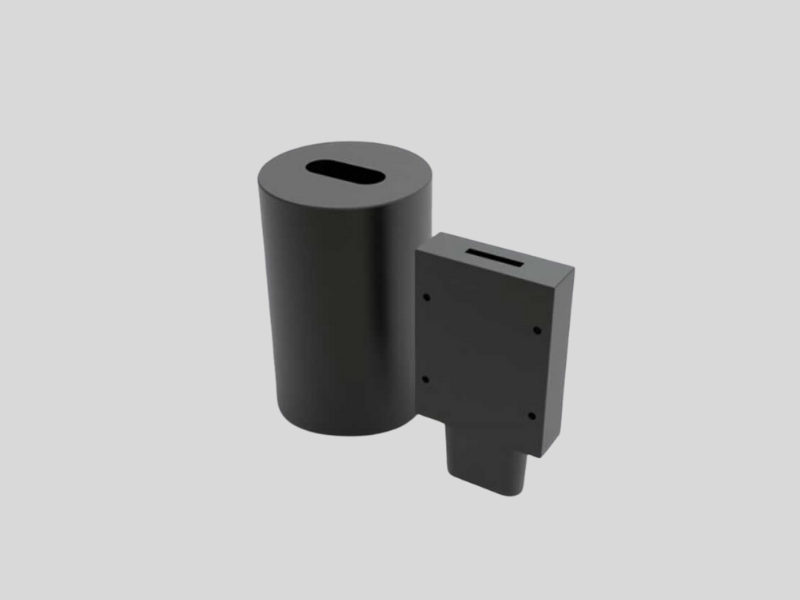

Molds and components made of graphite are widely preferred in continuous casting applications of non-ferrous and precious metals. Graphite ensures the solidified metal takes the desired shape and also contributes to the formation of a uniform crystal structure by providing effective heat transfer in the solidification zone.

The high mechanical strength, oxidation resistance, thermal shock resistance, and low porosity of the graphite material used are key factors that directly affect both product quality and service life.

Continuous casting applications are divided into two main categories: vertical and horizontal systems. The selection of graphite quality is determined by the type of metal to be cast, the application temperature, the mold design, and the casting method.