Glass Industry Applications

Glass Industry Applications

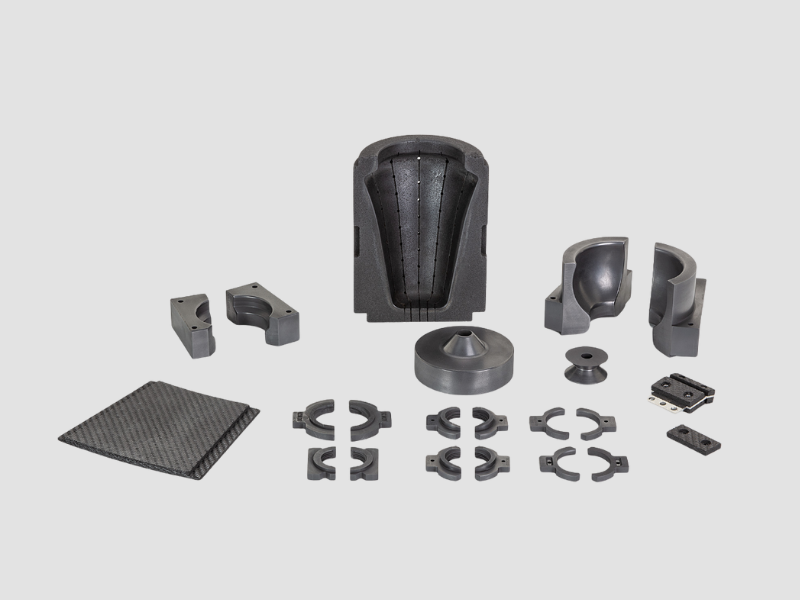

Graphite, thanks to its high-temperature resistance and superior physical properties, holds a significant place in glass industry applications. Many components used in glass production lines, such as carrier carbons, retaining carbons, transition squares, pusher parts, and tin bath edge carbons, are manufactured from graphite.

The grain size, oxidation resistance, and the dimensional and surface precision of the surfaces in contact with the glass are critical parameters that directly affect product performance. Therefore, the appropriate graphite grade must be carefully selected for the operating temperature, chemical environment, and mechanical requirements of each application.

The high chemical resistance, excellent thermal conductivity, and long service life offered by graphite have made it an indispensable engineering material in glass production processes. Heat-resistant carbon-graphite elements, particularly used in glass shaping, transportation, and guiding stages, ensure process continuity and product quality.